1.Definition and Importance of Pipe Fittings

Pipe fittings serve as the critical “functional joints” within piping systems, acting as core components for directing and controlling fluid flow. They fulfill four fundamental functions: connecting, redirecting, branching, and transitioning pipe diameters. These elements transform discrete pipelines into cohesive, flexible, and reliable transportation networks. Whether in energy pipelines spanning thousands of miles, intricate chemical plants, or urban underground drainage systems, pipe fittings silently determine the integrity, efficiency, and safety of these systems. Given the diverse shapes and complexities of piping systems, a wide variety of fittings are required to meet different demands.

At the functional level, pipe fittings demonstrate precision engineering value: connectors establish transport pathways, elbows guide flow direction and adapt to spatial constraints, tees enable flow distribution, while reducers facilitate smooth transitions between differing pipe diameters. These components work collectively to ensure fluids operate in a controlled and efficient manner throughout complex systems. Beyond these, numerous other types of pipe fittings exist, each possessing unique functions and applications, collectively forming indispensable components within piping systems. These additional fittings include, but are not limited to, blind flanges, flanges, valves, and others. They each play critical roles within the piping system, ensuring its smooth operation and safe usage.

The selection of pipe fittings must be strictly matched to the system's operating conditions—chemical environments require corrosion-resistant materials, high-temperature and high-pressure applications rely on special alloys, and proper sizing and pressure compatibility form the foundation for safe operation. Historically, major accidents caused by pipe fitting failures have been commonplace. For instance, in the 2010 Gulf of Mexico oil spill, the failure of critical blowout preventer components directly led to catastrophic consequences. This serves as a stark warning: though small in size, pipe fittings define the safety boundaries of the entire system. Their design and selection demand zero compromise.

2.Common Types and Functions of Pipe Fittings

Pipe fittings can be categorized into five types based on their common functions: connecting fittings, directional fittings, diverging fittings, reducer fittings, and sealing fittings.

2.1.Connecting Fittings (for connecting pipes): Flanges, pipe couplings, union fittings, ferrules, hose clamps.

2.1.1. Flange

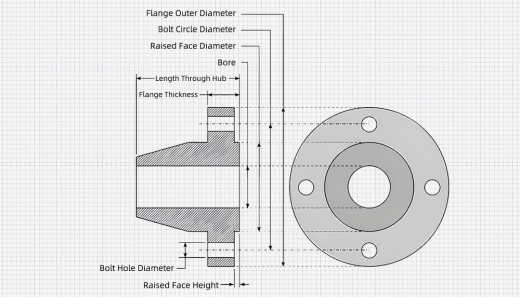

A flange, commonly referred to as a flange plate, is typically a disc-shaped metal component with multiple fixed holes. It serves to connect pipes, vessels, or secure shafts together. Flanges usually feature screw holes and threaded structures for fastening and are widely used in mechanical engineering. The standard connection method involves combining a flange, gasket, and bolts: a gasket is placed between two flanges, which are then tightly secured with bolts.

The variety of flanges is vast, with common materials including carbon steel, stainless steel, and alloy steel. Common types of flanges include:

(1)Threaded Flange

The design of threaded flanges resembles that of slip-on flanges, but features tapered threads. These threads are located on the inner bore and the inner surface of the outer diameter, enabling pipe connections without welding. They are ideal for low-pressure and low-temperature applications, suitable for pipelines transporting non-corrosive substances. A thread is present within the flange bore, mating with the external threads on the fitting. Here, threaded connections refer to avoiding welding in various scenarios. They primarily connect through threads that match the pipes being installed.

(2)Socket Weld Flange

Socket weld flanges refer to flanges where the pipe end is inserted into the stepped flange ring and welded on both the pipe end and the outer side. This connection method provides a secure joint and facilitates easier alignment during installation. Socket weld pipe flanges offer high rigidity, minimal welding distortion, and superior sealing performance. However, they are not suitable for critical service applications. In confined spaces, socket weld flanges are often used as an alternative to weld neck flanges. They are well-suited for high-pressure applications such as pipelines transporting corrosive fluids or hydraulic systems. Commonly employed in industries including boiler pressure vessels, petroleum, chemical processing, shipbuilding, pharmaceuticals, metallurgy, machinery, and stamped elbows for food processing.

(3)Blind Flange

A blind flange is a flat plate without any holes. Unlike other flanges primarily used to connect pipes, valves, or equipment, it is designed to seal the ends of pipe systems, valves, and pressure vessel openings. A blind flange resembles a boltable blank disc. Due to the high pressures it must withstand, blind flanges are typically large in size. They are used to seal unused pipes and valves. They are also commonly employed in locations requiring maintenance or potential future expansion.

(4)Weld Neck Flange

Weld-neck flanges (also known as necked butt-weld flanges, abbreviated as WN flanges) are pipe fittings manufactured from forged steel. They feature a tapered neck and a welded structure designed for direct butt welding to pipelines. These flanges achieve connection through double-sided butt welding with the pipeline, offering high connection strength, excellent stress resistance, superior sealing performance, and resistance to deformation.

Its structure employs a rational bell-shaped transition design, positioning the weld seam away from the sealing surface. This prevents weld temperature deformation from affecting sealing performance while providing excellent rigidity and elasticity. Consequently, necked butt-weld flanges are suitable for applications with significant pressure or temperature fluctuations and stringent sealing requirements. They are commonly found in high-temperature, high-pressure, and cryogenic piping systems, and are also widely used in pipelines transporting expensive, flammable, or explosive media.

The nominal pressure range for this flange is typically 1 to 25 MPa (i.e., PN1 to PN25). In standard applications, it is commonly used for connecting pipelines and valves rated at PN2.5 MPa and above.

(5)Slip-On Raised Face Flange (SORF)

Slip-On Raised Face Steel Pipe Flange, also known as a hubbed slip-on flange, is a type of flange where the pipe or fitting is inserted into the flange and connected to the equipment or pipeline via fillet welds.

The flange is manufactured from thick, standard-grade steel plate as required. As a variant of the slip-on flange, it features a short hub (neck), which enhances the flange's strength and improves its load-bearing capacity. This design allows it to be used in piping systems with higher pressure ratings.

The nominal pressure range for slip-on raised face flanges is typically 0.6 to 4.0 MPa.

(6)Lap Joint Flange

Lap Joint flanges are further divided into two types: welding neck ring lap joint flanges and slip-on ring lap joint flanges.A lap joint flange consists of two components: a stub end and a backing flange. The flange is slipped onto the stub end, and the stub end is welded to the pipe end. The flange remains free to rotate or move axially along the pipe, making it particularly suitable for piping systems that require frequent disassembly for inspection, maintenance, or cleaning.

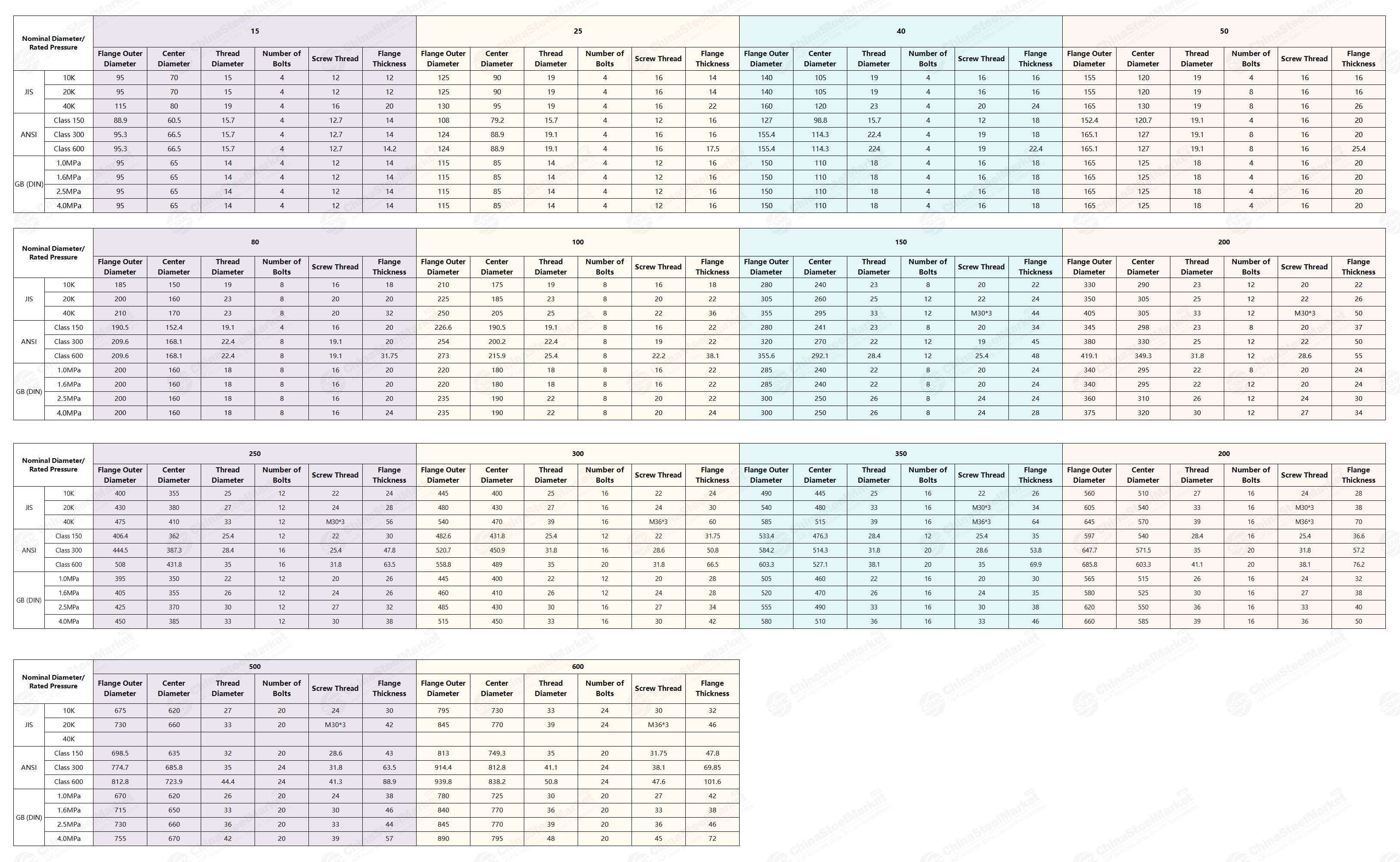

GB, ANSI, JIS Connection Flange Standard Comparison Table

2.1.2.Pipe Coupling

Pipe clamps are commonly found in metal piping systems. They are short pipe connectors, typically cylindrical in shape, with internal threads at both ends. Their function is to connect two externally threaded pipe ends together end-to-end via threading or welding, ensuring the continuity and seal integrity of the piping system. They are frequently used in galvanized steel pipe systems, plumbing, gas, and fire protection piping systems.

As a connecting pipe fitting, pipe couplings feature the following characteristics:

Threaded connection requiring PTFE tape or sealant for sealing;

Permanent connection that is difficult to disassemble after installation;

Emphasis on high strength, sealing performance, and pressure resistance.

2.1.3.Pipe union

A pipe union primarily consists of three parts: the nut, the female end, and the male end. This pipe fitting is forged from round steel or steel ingots and then machined. Its connection types include socket weld and threaded connections. Socket weld involves inserting the steel pipe into a socket hole for welding, hence the name “socket union.” Threaded connection involves screwing the steel pipe into a threaded hole for connection, hence the name “threaded union.” The primary manufacturing standards are ASME B16.11 and MSS SP 83.

Features of union:

Easy and quick connection with simple operation. Highly adaptable, enabling flexible handling even in confined spaces with densely arranged reinforcing bars.

2.1.4.Ferrule

The ferrule is a crucial component of ferrule-type pipe fittings, typically made of metal (such as stainless steel or copper) and featuring a sleeve-like structure. Its interior incorporates specialized features like sealing cones or internal cutting edges.

The operating principle is as follows: A pipe (such as seamless steel pipe) is inserted into the ferrule. By tightening the ferrule nut, the ferrule is compressed, causing the internal cutting edge to uniformly cut into the pipe's outer wall. Simultaneously, the sealing tapered surface of the ferrule mates with the tapered surface of the fitting body. This achieves pipe connection and sealing, ensuring stable fluid transmission (such as oil, gas, water, etc.) within the pipe and preventing leakage.

This ferrule is widely used in hydraulic systems, pneumatic systems, petrochemicals, nuclear power, and other fields demanding high sealing performance and connection reliability. It is suitable for connecting rigid metal pipes.

2.1.5.Hose Clamp

A hose clamp is an adjustable band secured by bolts or nuts, used to fasten the connection between flexible and rigid pipes.

The clamp adjusts the tension of the ring-shaped metal band via screws, tightly wrapping the hose and applying uniform pressure to ensure a snug fit between the hose and fitting, preventing leaks or loosening.

Features:

Compact, lightweight, and easy to operate; commonly features screw-type or rack-and-pinion tightening mechanisms; typically constructed from corrosion-resistant stainless steel or galvanized carbon steel; limited tightening range, suitable for soft materials.

In various piping systems—such as automotive fuel lines, water hoses, or industrial gas/liquid conveyance pipelines—tightening hose clamps securely fastens fittings to prevent leaks, ensuring uninterrupted medium flow. Primary Applications/Scenarios: - Household water hose connections (e.g., washing machine inlet hoses) - Automotive fuel and water line hose connections - Industrial hose connections (e.g., air, water, fuel lines) for quick securing.

2.2.Directional Fittings (Pipe Fittings for Changing Pipe Direction): Elbows, Bend Pipes.

2.2.1.Elbow

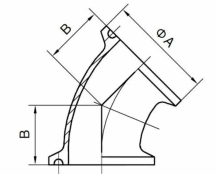

Elbows are a common type of pipe fitting used in plumbing installations to connect two pipes of the same or different nominal diameters. They serve as connectors at pipe bends, altering the direction of the pipeline. They enable the pipeline to make turns at 90°, 45°, 180°, and various other angles. Elbows are categorized by common angles into 45° elbows, 90° elbows, and 180° elbows. By manufacturing process, they are categorized as welded elbows, stamped elbows, formed elbows, and cast elbows.

45-degree (1/8-turn) elbow primary functions:

Changing flow direction: A 45-degree elbow is a highly practical component when fluid flow within a pipeline requires a 45-degree deflection.

Reduced flow resistance: Compared to 90-degree or 180-degree elbows, the 45-degree elbow imposes relatively lower flow resistance, helping maintain fluid velocity and pressure.

Adaptable layout: In complex piping configurations, the 45-degree elbow offers greater flexibility to accommodate diverse directional connection requirements.

Primary Functions of 90-Degree Elbows:

Changing Fluid Flow Direction: The most fundamental function is to enable a 90-degree change in fluid direction within piping systems.

Connecting Pipes at Different Angles: In complex piping systems, pipes often connect at varying angles. 90-degree elbows facilitate the connection of these differently oriented pipes, ensuring the continuity and integrity of the entire piping system.

Enhancing piping layout flexibility: By utilizing 90-degree elbows, designers can arrange piping more flexibly to better accommodate structural and spatial requirements of buildings.

Primary Functions of 180-Degree Elbow:

Fluid Reversal: The core function of a 180-degree return elbow is to reverse the fluid flow direction by 180 degrees within the pipeline. This is critical in specific pipeline layouts and connection scenarios.

Space Optimization and Layout: In confined or complex piping systems, 180-degree return elbows optimize layout by reducing required pipe length and the number of fittings. This helps lower material costs, simplify installation processes, and enhance construction efficiency.

Stress Relief: Piping systems may experience stress from gravity, pressure, or external factors. Incorporating 180-degree return elbows can mitigate these stresses to some extent, improving the stability and reliability of the piping system.

Features: Elbows ensure smooth fluid flow and minimize pressure loss.

Applications: Widely used for pipe directional changes in HVAC systems, water supply pipelines, and similar applications.

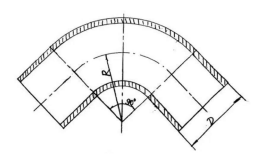

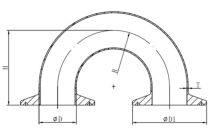

2.2.2.Pipe Bend

Pipe Bends, like elbows, are pipe fittings used to alter the direction of piping. A bend is a pipe section that has been appropriately curved to suit its application, typically manufactured to meet specific requirements. Compared to elbows, bends are generally longer. Typically, an elbow has a radius (R) of 1 to 2 times the pipe diameter, while a bend has a radius greater than 2 times the pipe diameter.

2.3 Branch-type fittings (fittings that add pipe branches): Tee, Cross.

2.3.1.Tee

A tee, also known as a tee fitting or tee connector, is a pipe fitting used for branching pipelines and altering fluid flow direction. Typically designed in a “T” shape, it features one inlet and two outlets to merge or diverge fluid streams. Tees are categorized into equal-diameter tees and reducer tees (also called reducing tees), selectable based on pipe diameter requirements. Common materials include carbon steel, stainless steel, copper, plastic, and other materials. They are widely used in branching or convergence points of water supply, drainage, and other systems.

2.3.2.Cross

Cross features four openings arranged in a cross shape, designed to connect four pipes of identical diameter and perpendicular alignment. Primarily used for branching or redirecting flow, it serves as a common “intersection” in plumbing and heating pipe networks. By size, tees are categorized as equal-diameter or reducer types; by connection method, common variants include butt-weld and threaded fittings.

2.4.Reducing Fittings (Pipe Fittings for Changing Pipe Diameter): Reducer, Reducing Elbow,Branch Connection Fitting .

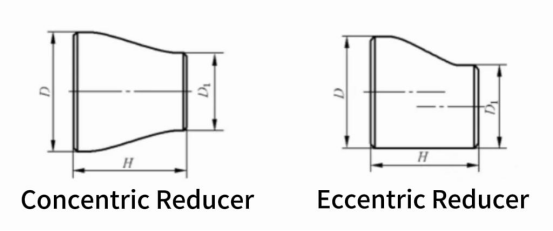

2.4.1.Reducer

Also known as a reducer fitting, it connects two pipes of different diameters. Primarily used for pipe connections with minor diameter changes. There are two types: concentric reducers and eccentric reducers. Their forms are as follows:

As shown in the diagram:

Eccentric reducers are suitable for pipeline laying when the bottom elevations of the reducers are aligned; they can also be used for overhead installations.

Concentric reducers are suitable for overhead use but not for laying, as their bottom elevations are not aligned.

Scope of Application

(1) Reducers are required when fluid flow rates in pipelines change—such as increasing or decreasing—while maintaining minimal velocity variation.

(2) Reducers are necessary at pump inlets to prevent cavitation.

(3) Reducers are also used at connections to instruments like flow meters and control valves to match their fitting specifications.

2.4.2.Reducing Elbow

Reducing elbows not only serve the basic function of altering pipeline flow direction like standard equal-diameter elbows, but also enable changes in pipe diameter during turns. They perform the same role as reducers, though reducers cannot be used for directional changes. Their price is approximately double that of equal-diameter elbows. At some construction sites, a single elbow welded together with a reducer is used as a substitute for this product. Materials include carbon steel, stainless steel, alloy steel, PVC, cast steel, and others.

2.4.3.Branch Connection Fitting

Branch connection fittings, also known as branch saddles, saddle fittings, or saddle-type pipe joints, are primarily used as reinforced pipe fittings for branch connections. They replace alternative branch connection methods such as reducer tees, reinforcement plates, and reinforced pipe sections. They offer significant advantages including safety and reliability, cost reduction, simplified construction, improved flow path for media, standardized series, and convenient design selection. Their use is increasingly widespread in high-pressure, high-temperature, large-diameter, and thick-walled pipelines, replacing traditional branch connection methods.

2.5.Sealing Components (Pipe Fittings for Pipeline Sealing): Gaskets, Flange Blind Flanges, Pipe Plugs, Blind Flanges, End Caps, Plugs.

2.5.1.Gasket

A material placed between two flat surfaces to enhance sealing, serving as a sealing element positioned between tight sealing surfaces to prevent fluid leakage.

Gaskets are pipe fittings clamped between flanges to ensure sealing. As a critical pipe component, gaskets provide sealing between flanges. Utilizing the pressure from flange fastening bolts, they deform to fill the gap between flanges, thereby preventing leakage.

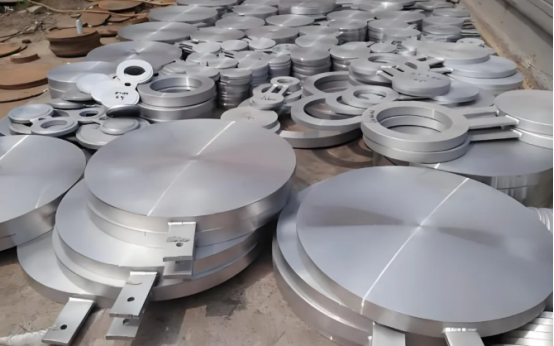

2.5.2.Blind flange

The previous section provided a general overview of the various classifications of flanges. A blind flange is a specialized flange without a through-hole, also known as a flange cover, blind flange, blind plate flange, or head flange. It is primarily used to seal pipe ends or equipment interfaces. Its function is similar to that of a pipe head or cap, but the blind flange employs a flanged connection, making it removable and suitable for applications requiring future maintenance or expansion. In contrast, pipe heads and caps are typically welded in place, non-removable, and generally used for permanent sealing.

2.5.3.Pipe Plug

Typically refers to cylindrical or threaded fittings with internal and external threads, secured via threaded connections at pipe joints or openings. These are used to seal pipe sections or branch connections, preventing water or gas leakage. They are also suitable for temporary pipe closures during scenarios such as pressure testing, pipeline maintenance, construction-related temporary sealing, and system commissioning.

Features: Easy installation, removable, suitable for applications requiring frequent assembly and disassembly. Common materials include metals (e.g., steel, copper) and plastics, selectable based on pipeline medium and operating environment.

2.5.4.Blind plate

A blind plate (or simply "blind") refers to any solid barrier used to completely seal a pipeline or equipment port, either permanently or temporarily, to prevent the flow of media. Its core function is to provide absolute and reliable physical isolation.

Unlike a blind flange, which is specifically designed to be installed between two standard flanges, a blind plate can be mounted in various locations: at pipe ends, between flanges, on manways, equipment openings, and other access points.

2.5.5.Pipe cap

A pipe cap is a component used to seal the ends of a vessel to achieve medium isolation, also known as an end cover, and is classified as a boiler component within pressure vessels. Based on surface shape, pipe caps can be categorized into convex, conical, flat plate, and composite types. Convex pipe caps include hemispherical, elliptical, and dish-shaped variants. They are welded to the vessel shell and are manufactured from materials including carbon steel, stainless steel, alloy steel, and non-ferrous metals. They are widely used in storage tanks, reactors, and gas cylinders across industries such as petrochemicals, nuclear power, food processing, and pharmaceuticals. For gas cylinders, composite heads with convex surfaces facing inward balance strength and safety requirements. However, in solid rocket motor casings, complex stress patterns can lead to low-pressure burst hazards.

2.5.6.Plug

A plug is a broader concept than a pipe plug, generally referring to fittings used to seal unwanted openings in pipes. Plugs come in various shapes and connection methods, such as flat, spherical, conical, and cylindrical types, allowing selection based on pipe geometry, size, and application requirements.

Plug types are numerous and their applications extensive—anywhere pipes exist, plugs are employed. Based on material, they can be broadly categorized into plastic plugs, iron plugs, stainless steel plugs, copper plugs, aluminum plugs, and so forth. Plugs find use in countless everyday applications, such as water pipes and mechanical equipment. Within the hydraulic industry, plugs are most commonly used in construction machinery.

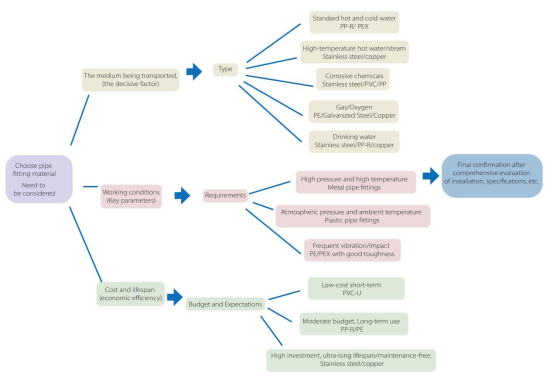

3.Performance and Selection of Pipe Fittings Made of Different Materials

Pipe fittings come in a variety of materials, commonly including:

1. Carbon steel: High strength, moderate price, and widely used.

2. Stainless steel: Good corrosion resistance, suitable for corrosive media.

3. Copper pipe fittings: Good thermal conductivity, mostly used in HVAC systems.

4. Plastic pipe fittings (PVC, PE, etc.): Lightweight, corrosion-resistant, suitable for water supply and drainage.

5. Cast iron: Good wear resistance, mostly used for drainage pipes.

When selecting pipe fittings, factors such as the type of media, temperature, pressure, corrosivity, and economic considerations should be taken into account.

Choosing the right pipe fittings requires a systematic consideration of several key factors. The basic principle is to ensure that the size and material of the pipe fittings are a perfect match for the piping system, including the pipe diameter, the material itself, and the intended use of the system. Based on this, it is crucial to verify that the fittings can withstand the specific operating temperature and pressure conditions of the system and comply with all relevant industry safety and quality standards.

When it comes to material selection, it is essential to carefully evaluate the operating temperature and pressure, the properties of the fluid being transported, corrosion resistance requirements, and external environmental factors. The fitting materials must be matched with the pipe materials to ensure chemical and physical compatibility. Finally, its durability, ease of installation, and overall cost-effectiveness must be comprehensively evaluated to meet all the requirements of the specific application scenario.

4.Industry Development Trends of Pipe Fittings

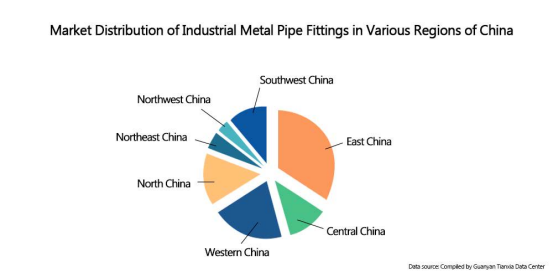

China's industrial metal pipe fittings market has entered a new stage of steady growth in scale and continuous upgrading of structure. In 2025, the market size is approximately 980 billion yuan, representing a year-on-year growth of 5.5%. Among them, traditional mainstream products such as elbows, tees, reducers and flanges account for more than 60% of the market share, while large-diameter, high-pressure, corrosion-resistant and ultra-low temperature pipe fittings have become the core demand driving the growth of the high-end market. In terms of industrial layout, about 68% of the country's large-scale production capacity is concentrated in five provinces: Jiangsu, Zhejiang, Shandong, Guangdong and Hebei, forming a significant East China industrial cluster.

China is not only the world's pipe fittings production center, accounting for more than half of the global output, but also an important exporter, with exports accounting for about 20% of the global total. Exports to countries along the Belt and Road Initiative account for more than 60% of the total, with Southeast Asia, the Middle East, Africa and South America becoming key growth markets. In terms of product structure, although steel pipes still dominate as the traditional mainstream, their growth has slowed down; while high-end products such as stainless steel pipes and copper pipes are showing a more rapid growth momentum, clearly reflecting the overall trend of the industry upgrading towards higher added value.

In recent years, my country's infrastructure construction, manufacturing upgrades, and consumption growth have continuously driven the steady growth in demand for industrial metal pipe fittings. Meanwhile, the rapid development of emerging fields such as new energy and new materials has opened up unprecedented market opportunities for the industry. As a key component of fluid systems, this industry is simultaneously driven by both macro-market expansion and technological innovation. With increasing demand from various sectors, from automobiles and construction to high-end manufacturing, the market size will continue to expand. Looking to the future, the application of new materials and energy structure transformation will not only bring broader markets but also drive the industry towards high-tech and high-performance upgrades, presenting abundant opportunities for product innovation and technological progress.

For the steel industry, pipe fittings are not only important downstream products, but also a barometer reflecting material technology upgrades and changes in market demand. Currently, the development of the pipe fittings industry, which uses steel as its main raw material, is closely focused on three dimensions: improving material performance, innovating manufacturing models, and expanding downstream applications.

The demand for high-performance special steels is becoming increasingly prominent.

Extreme working conditions such as deep-sea energy development, supercritical power plants, and high-end chemical industries, place extreme demands on the pressure resistance, corrosion resistance, and low-temperature toughness of pipe fittings. This has directly driven the rapid growth in the application of special steels such as high-strength low-alloy steel, super duplex stainless steel, and nickel-based alloys in key pipe fittings. The purity, uniformity, and traceability of performance data of steel have become key factors in winning orders from high-end pipe fitting manufacturers.

Intelligent manufacturing is driving deep collaboration in the steel supply chain. The digital transformation of pipe fitting manufacturing, from design simulation to automated production, requires more precise and reliable upstream steel supply. Just-in-Time (JIT) delivery, the provision of customized pre-processed blanks, and the inclusion of complete quality certifications are shifting from value-added services to core requirements. The role of the steel processing service center has therefore expanded from trade distribution to a material solutions provider.

Green and life-cycle costs have become important considerations in material selection.

In the context of low-carbon development, downstream industries are paying more attention to the comprehensive cost and environmental benefits of pipe fittings throughout their entire life cycle. Pipe fittings made of high-performance, long-life steel may have a higher initial investment, but they can gain long-term advantages in terms of economy and emissions reduction by reducing maintenance and replacement. Meanwhile, the market for recycling and remanufacturing high-value alloy steel pipe fittings is also emerging, opening up new avenues for steel recycling.

Emerging strategic projects create clear incremental demand.

The expansion of the liquefied natural gas (LNG) industry continues to drive stable demand for ultra-low temperature resistant steel pipe fittings. The rise of the hydrogen energy industry chain has posed new challenges to the hydrogen embrittlement resistance of hydrogen transportation pipeline materials, and is giving rise to new material standards and product series. These emerging fields provide clear high-value-added market exports for specialty steels.

The development trend in the pipe fittings sector has pointed out a clear direction for the steel industry: shifting from providing standardized products to providing high-value-added materials and in-depth services to meet the needs of high performance, precision, greenness, and specific scenarios. Grasping this trend will help steel companies optimize their product structure, deepen supply chain collaboration, and take the initiative in future market competition. CSMC will continue to monitor the development of the steel industry and actively provide useful information to its clients.

We sincerely hope that the information we provide can make more beneficial value. In addition, we sincerely invite you to leave valuable comments and advice on our website. We will follow your comments and advice at any time on our website.

CSMC-Empowering small and medium-scale steel purchasing.

Editor: Kyra Hana

Mail: cs@chinasteelmarket.com

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: