25/09/2025 13:16:24

25/09/2025 13:16:24

2 answers in:

Product Standards

2 answers in:

Product Standards

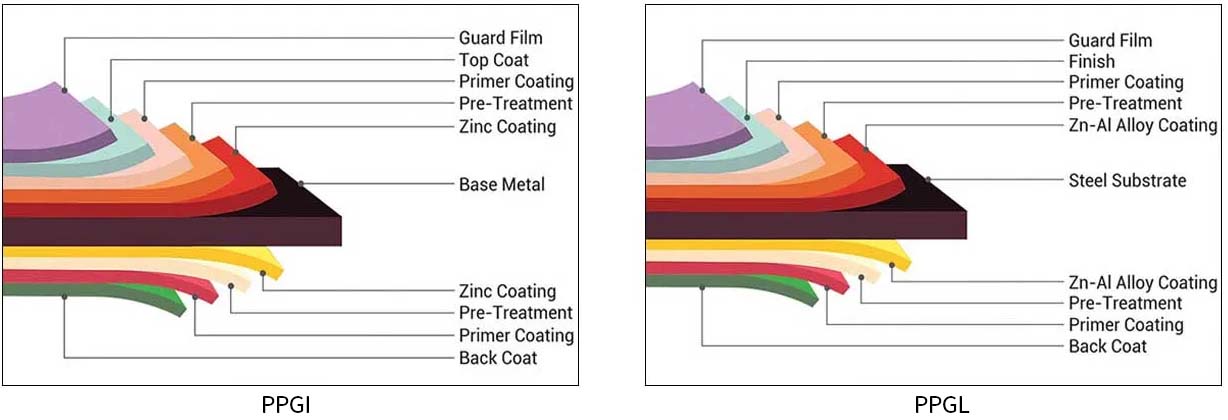

PPGI is galvanized color-coated steel sheet, while PPGL is galvalume color-coated steel sheet. While both are color-coated, they differ in their base material: one is galvanized, the other is galvalume. This difference in base material determines their performance differences.

PPGI (Galvanized steel sheet): PPGI is a high-end color-coated steel sheet with excellent weather resistance and corrosion resistance, making it suitable for exterior walls and roofs of high-end buildings. PPGI has very good weather resistance and corrosion resistance, making it a very suitable material for high-end construction. The coating thickness of PPI color steel coil is generally around 20 microns, and it has excellent light resistance, water resistance, acid and alkali resistance and pollution resistance.

PPGL (Galvalume Steel Coil): PPGL steel coil has excellent corrosion resistance and high temperature stability, and is suitable for construction materials in harsh environments such as seaside and industrial areas. PPGL color-coated steel coils have excellent corrosion resistance and high-temperature stability, and can be used in harsh marine and industrial environments. The coating of PPGL is generally composed of 50% aluminum, 50% zinc and organic coating, which extends the service life of the color-coated steel coil.

The base materials are different: PPGI (polytetrafluoroethylene) is the abbreviation for pre-painted galvanized steel, while PPGL is the abbreviation for pre-painted galvanized steel. As the name suggests, PPGI uses galvanized sheet (with a coating of zinc) as the base metal. PPGL is based on a galvanized steel sheet, which is coated with 55% aluminum, 43.3% zinc and 1.6% silicon. This is the main difference between PPGI and PPGL, which further impacts their functions and applications.

Different lifespans: Both zinc and aluminum-zinc layers are used to protect metal from rusting, thereby extending its service life. For galvanized steel sheets, when the galvanized layer is completely corroded, the base material will be damaged. Generally speaking, the service life of galvanized sheet can reach 10 to 15 years. The aluminum and zinc alloys form microscopic grain regions. The zinc-rich phase corrodes preferentially, while the aluminum-rich phase corrodes very slowly. Therefore, Al-Zn coating is more corrosion-resistant than galvanized steel sheet. According to data, the service life of polylactic acid is 3 times longer than that of PPGI.

Appearance Difference: The surface of PPGL sheets is smoother than that of PPGI sheets. This is because aluminum adheres better than zinc. For the same reason, PPGL sheets can be painted directly without pre-treatment. However, PPGI sheets require pre-treatment.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: