30/07/2025 10:35:21

30/07/2025 10:35:21

2 answers in:

Other

2 answers in:

Other

Mn13 steel plate, also known as Mn13 high-manganese steel plate, Mn13 non-magnetic steel plate, or Mn13 sheet, is a special high-manganese wear-resistant steel that plays an important role in industrial production and engineering applications.

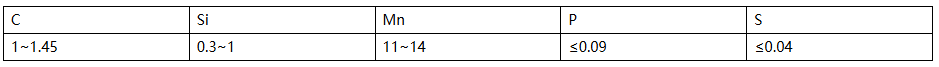

Composition: Mn13 steel plate's primary component is manganese (Mn), with a content as high as 11% to 14%, and carbon (C) between 1.1% and 1.4%. It also contains small amounts of elements such as silicon (Si) and phosphorus (P).

Properties:

Wear Resistance: The high manganese content provides excellent wear resistance, enabling it to maintain stable performance over time in various harsh environments.

Impact Resistance: Even when parts are worn to very thin thicknesses, they can still withstand significant impact loads without breaking.

Toughness: Demonstrates excellent toughness and is not prone to fracture.

Non-magnetic: Mn13 steel plate is a non-magnetic austenitic steel.

Machinability and Weldability: It exhibits excellent machinability and weldability, facilitating cutting, bending, welding, and other processing operations.

Mn13 steel is a high-carbon, high-manganese austenitic steel. Its chemical composition is as follows:

Core Characteristics:

Excellent work-hardening ability: The core of Mn13 steel. When subjected to strong impact or high-stress compression, the surface austenite rapidly induces numerous dislocations and undergoes a martensitic transformation. The hardness can dramatically increase from an initial hardness of around HB200 to over HB500, forming a tough, wear-resistant surface layer while maintaining excellent toughness in the core.

Excellent impact wear resistance: Under high impact loads, such as gouging and impact wear, the hardened layer effectively resists gouging, demonstrating a service life far exceeding that of ordinary wear-resistant steels.

Excellent toughness: The high manganese content ensures the high toughness of the austenite matrix, enabling it to absorb significant impact energy without brittle fracture, thus preventing catastrophic failure under harsh operating conditions.

Moderate initial hardness and ease of processing: After solution treatment (water toughening), the material is in a soft and tough state (HB180-220), which is convenient for cutting, drilling, forming and other mechanical processing, providing convenience for the manufacture of complex wear-resistant parts.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: