Steel pipes serve as indispensable materials in modern industry, construction, energy, and daily life. Their long-term durability and operational safety directly impact the reliability of infrastructure, the continuity of production operations, and the economic efficiency throughout their entire lifecycle. In various corrosive environments and complex operating conditions, steel pipes without effective protection inevitably deteriorate in performance, leading to major engineering risks such as leaks and fractures. Therefore, the protection of steel pipes is of paramount importance. Coatings play a vital role in steel pipe protection by providing both corrosion resistance and mechanical protection, thereby extending the service life of the pipes.

1. The Importance of Coatings

In 2010, a 54-year-old natural gas pipeline in San Bruno, California, ruptured and exploded due to a combination of manufacturing defects in the weld seam and failure of the external anti-corrosion coating system. The incident resulted in multiple casualties and significant property damage. The National Transportation Safety Board (NTSB) investigation confirmed that the failure of the corrosion protection system was a key contributing factor to the accident. This case profoundly highlights the critical importance of coating integrity to pipeline corrosion protection systems and the long-term safe operation of pipelines.

The photo shows the disaster scene in St. Bruno at the time

Corrosion of steel pipes is a spontaneous and continuous electrochemical or chemical process. Without effective protection, corrosion significantly shortens the design life of steel pipes, leading to leaks, pollution, production shutdowns, and even catastrophic accidents, resulting in substantial direct and indirect economic losses. Steel pipe coating systems provide critical corrosion protection through mechanisms such as physical isolation and electrochemical shielding, while also delivering multiple functional benefits including drag reduction, wear resistance, thermal insulation, and aesthetic enhancement. The quality of coating performance and the appropriateness of coating selection have become key factors influencing the quality, cost, and safety of engineering projects.

1.1 Coatings provide barrier protection (physical isolation) for steel pipes.

Coatings form a dense, continuous, low-permeability barrier on the steel pipe surface, physically isolating the metal substrate from corrosive environments (moisture, oxygen, electrolytes, chemical media). This constitutes their most fundamental function.

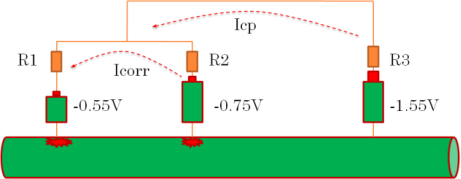

1.2 Coatings provide electrochemical protection (cathodic protection) for steel pipes.

For zinc-rich coatings (such as hot-dip galvanizing and zinc-rich primers), zinc acts as a sacrificial anode, providing cathodic protection to the steel substrate through preferential corrosion. Even with minor coating damage, it continues to shield exposed steel from corrosion.

1.3 Additional Functions of Coatings

Beyond corrosion protection, coatings are engineered with multiple specialized functions:

Friction Reduction & Efficiency Enhancement: Internal pipeline coatings minimize fluid friction resistance, improving transportation efficiency.

Mechanical Protection: Enhanced resistance to abrasion, impact, and soil stress.

Thermal Insulation & Energy Conservation: Insulating coatings minimize energy loss during transportation.

Safety Marking: Color-coded systems provide visual warnings regarding pipeline contents and flow direction.

Furthermore, beyond the protective function of coatings for steel pipe foundations, from a full lifecycle cost analysis of engineering projects, the coating system—which accounts for a relatively small portion of the initial investment in steel pipes—directly determines maintenance frequency, overhaul costs, and potential risks over decades of operational cycles. Therefore, the coating component of steel pipes should not be regarded as basic consumable material, but rather as a strategic asset protection investment with significant value leverage. The scientific selection and reliable quality of coatings form the critical foundation for ensuring the long-term safe operation and economic viability of engineering projects.

2. Coating Classification

Having established the core premise that coating technology plays a vital role in safeguarding steel pipe performance and extending project lifespans, a critical question arises: How should we systematically identify and categorize coating technologies themselves when faced with steel pipes operating in diverse corrosion environments and serving different functional requirements? We will now classify the mainstream steel pipe coatings available on the market based on three primary factors: coating location, coating function and application environment, and coating material type.

2.1. By coating location

Internal Coating

According to reliable records from the last century, internal pipeline coatings were initially proposed to prevent corrosion of the pipe walls. They were first applied to pipelines transporting sulfur-containing crude oil and natural gas. Subsequent experimental evidence revealed that internal coatings not only effectively prevent corrosion but also significantly enhance pipeline gas transmission capacity. Domestic and international literature indicates that applying internal coatings to gas transmission pipelines can increase throughput by 5% to 20%.

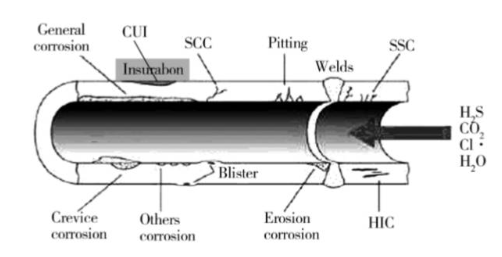

The core function of modern internal coatings remains corrosion prevention, safeguarding transmission efficiency and product purity. This function is determined by the pipeline's transported medium. When conveying oil, gas, or chemicals, the coating must resist corrosive elements like hydrogen sulfide and carbon dioxide. In water supply and food applications, it must meet sanitary standards and prevent metal ion leaching. Reducing friction is another critical function: a smooth coating lowers fluid resistance, enhancing long-distance pipeline efficiency. For abrasive media like mineral slurries or ash residues, specialized wear-resistant linings such as epoxy ceramics are required. Common systems include fusion-bonded epoxy powder, liquid epoxy, and cement mortar linings. Quality control hinges on achieving extremely high surface cleanliness, complete coating coverage, and outstanding resistance to media immersion.

Image shows types of corrosion inside pipelines

External Coating

The external coating serves as the primary barrier protecting steel pipes from external environmental corrosion, with its performance directly determining the pipeline's service life. Its main functions include isolating moisture, salts, chemicals, and microorganisms in the soil while resisting mechanical damage during transportation, installation, and backfilling. Modern external coatings must also exhibit excellent compatibility with cathodic protection systems, with resistance to cathodic delamination being a critical metric. The current mainstream system employs a three-layer polyethylene/polypropylene structure. This system combines the adhesion of an epoxy primer with the mechanical protection and weather resistance of a polyolefin topcoat, making it the standard configuration for both onshore and subsea pipelines. Coatings such as fusion-bonded epoxy powder and polyurethane are also applied in specific environments. Selection requires comprehensive consideration of soil corrosivity, application methods, and long-term environmental stresses. Among these, controlling the quality of field joint repairs is both the key and the challenge in ensuring continuous protection along the entire pipeline route.

Internal and External Composite Coating

Internal and external composite coating provides comprehensive ultimate protection for steel pipes, typically deployed in extremely demanding or high-value scenarios. Typical applications include subsea pipelines, where the exterior endures high pressure, high salinity, and mechanical risks while the interior transports media potentially containing corrosive components; and process pipelines traversing sensitive areas or conveying highly corrosive media. This technology requires the internal and external coating systems to be fully matched in both process and performance, with precision quality control throughout the entire production process. From dual-surface preparation and simultaneous coating application to curing, each stage allows minimal tolerance for error. Strict independent performance verification must be conducted for both inner and outer coatings. Consequently, despite offering the highest protection level, its substantial overall cost typically limits its application to critical pipeline projects where maintenance expenses are prohibitively high.

2.2 By Function and Application Environment

Anti-corrosion Coating

Anti-corrosion coatings represent the most widely applied category among steel pipe coatings. The primary principle of corrosion protection lies in preventing corrosive media such as H₂O, Cl⁻, and SO₂ in the environment from penetrating the metal surface. This isolates the corrosive media from the metal surface, thereby preventing metal corrosion.

According to relevant statistics, metal corrosion causes annual losses equivalent to approximately 5% of China's gross domestic product, with pipeline corrosion accounting for a significant portion of this figure. With China's sustained rapid economic growth, energy demand continues to rise, driving an expansion in pipeline construction,urban planning projects involve countless gas, water, and heating pipelines, making corrosion protection increasingly critical. This directly impacts the anti-corrosion performance and operational lifespan of pipelines. Therefore, intensifying research on pipeline anti-corrosion coatings holds significant importance for overall corrosion control.

The design of anti-corrosion coatings must precisely match the characteristics of the corrosive environment. Chemical anti-corrosion coatings, represented by epoxy and phenolic systems, effectively isolate acids, alkalis, salts, and various chemical media by forming a dense, chemically inert barrier on metal surfaces. Such coatings are indispensable for critical pipelines in chemical plants, oil and gas fields, and offshore platforms. For instance, high-performance epoxy linings are standard configurations ensuring long-term safe operation in acidic gathering pipelines of North American shale gas fields and large petrochemical complexes in the Middle East. In contrast, electrochemical corrosion protection coatings operate on the sacrificial anode principle, with zinc, aluminum, and their alloy coatings being typical examples. When the coating is damaged, the more negatively charged metal coating corrodes preferentially, providing continuous cathodic protection to the steel substrate. This mechanism offers significant advantages for structures exposed to the atmosphere long-term yet difficult to maintain frequently. Globally, from European high-speed rail noise barriers and North American high-voltage transmission towers to East Asian cross-sea bridge cables, hot-dip galvanizing and next-generation zinc-aluminum-magnesium coatings have become the standard guarantee for durability. For buried and submerged environments, soil/water corrosion protection coatings must withstand more complex stresses. Systems like triple-layer polyethylene and fusion-bonded epoxy powder not only resist long-term moisture and electrolyte penetration but also exhibit excellent resistance to soil stress cracking and microbial erosion. These coatings serve as the “standard armor” for modern energy arteries. Whether it's natural gas pipelines traversing Central Asia, oil pipelines crossing the seabed of Northern Europe, or national-level projects like China's “West-to-East Gas Pipeline,” all rely on such coating systems to ensure decades of design life.

High-Temperature Resistant Coating

High-temperature resistant coatings are a specialized category of protective coating materials designed for steel pipe surfaces. Their primary function is to shield steel pipes from high-temperature oxidation, corrosion, and erosion by corrosive media, thermal stress damage, thermal radiation, and heat conduction losses in high-temperature environments. These coatings are commonly used in high-temperature piping systems within industries such as petrochemicals, boilers, heat exchangers, and power generation.

In high-temperature service environments, coating technology must address material failure under thermal stress. For high-temperature resistant coatings, selection strictly depends on the temperature window and medium composition. Within the medium-to-low temperature range (200-400°C), organic high-temperature coatings see widespread application. Silicone-modified coatings and certain specialty epoxy systems maintain protective functionality by enhancing molecular chain thermal stability, commonly found on industrial steam pipelines and heat exchange systems. When temperatures exceed 400°C, inorganic coatings become the sole viable option. Silicate-based and ceramic-based coatings provide physical isolation and oxidation resistance by forming in-situ high-temperature stable phases (e.g., spinel, glaze layers) on metal surfaces. For instance, in extreme environments like boiler water-cooled wall tubes in power plants or high-temperature flue gas ducts in refinery catalytic cracking units, these coatings are critical technologies for resisting high-temperature oxidation, thermal corrosion, and coking/slagging. Their performance directly impacts the thermal efficiency and operational lifespan of the equipment. Additionally, there exists a type of heat transfer control coating that focuses on reducing thermal conductivity at the surface of steel pipes. Coatings containing ceramic particles or other insulating materials can decrease heat dissipation from the pipe wall, thereby enhancing thermal efficiency.

Wear-Resistant Coating

A wear-resistant coating is a protective layer applied to steel pipe surfaces to enhance resistance against abrasion, erosion, scouring, and mechanical friction damage. When transporting fluids containing particles, solid suspensions, high-velocity fluids, or high-impact media, steel pipes are prone to wear and erosion failure. Wear-resistant coatings can significantly extend the service life of steel pipes, reduce maintenance costs, and minimize downtime for repairs.

For operating conditions involving physical wear, the design of wear-resistant coatings requires a thorough understanding of wear mechanisms. Sliding wear demands coatings with low friction coefficients and high hardness; highly cross-linked epoxy and nylon coatings (polymer/organic wear-resistant coatings and linings) perform well in such scenarios (e.g., material conveying chutes). Impact wear places higher demands on coating toughness. Ceramic-metal composite coatings or ultra-high molecular weight polyethylene linings (polymer/organic wear-resistant coatings and linings) absorb energy through plastic deformation, protecting the substrate. Their value has been validated in slurry pipelines at mining processing plants and coal transportation pipelines in the coal industry. The most demanding conditions involve cavitation or liquid erosion, caused by high-pressure microjets from collapsing fluid bubbles. These environments require coatings with both excellent elasticity to cushion impacts and sufficient hardness to resist cutting. Elastic polyurethane and specialty synthetic rubber linings (elastic wear-resistant linings with impact and fatigue resistance) provide effective solutions for such challenges. They are widely applied in large turbine flow-through components at hydroelectric power stations and the inner walls of slurry pump housings on dredgers.

Decorative Coatings

Beyond fulfilling fundamental protective functions, decorative coatings also meet aesthetic and sustainability requirements. Their technical focus lies in maintaining color and gloss under long-term environmental exposure, achieved through the synergistic action of high-performance pigments, UV absorbers, and stabilizers in the formulation. Simultaneously, as global environmental regulations tighten, water-based and powder systems with low or zero VOC content are rapidly replacing traditional solvent-based coatings. From the curtain wall steel structure of Dubai's Burj Khalifa to the interior spatial framework of Singapore's Changi Airport, these iconic structures not only showcase coatings' exceptional weather resistance and decorative effects but also demonstrate their compliance value within green building certification systems.

2.3 By Material Type

Organic Coatings

Organic coating systems represent the most widely applied and technologically dynamic category in industrial applications. Their core components feature carbon chains as the backbone, with performance diversification achieved through chemical modification of synthetic resins. Thermosetting resin coatings, such as epoxy, polyurethane, and unsaturated polyester, form irreversible three-dimensional crosslinked networks during curing. This confers excellent adhesion, hardness, and chemical solvent resistance. Among these, fusion-bonded epoxy powder coatings have become the standard anti-corrosion option for onshore and subsea pipelines worldwide due to their outstanding adhesion and cathodic delamination resistance. Thermoplastic resin coatings, represented by polyethylene, polypropylene, and polyvinyl chloride, are formed through physical melting and cooling. They offer outstanding flexibility, impact resistance, and water vapor barrier properties. The three-layer polyethylene/polypropylene structure leverages the mechanical protection advantages of the thermoplastic polyolefin top layer combined with the adhesion benefits of the epoxy base layer, forming a composite system with outstanding performance. Furthermore, through composite modification techniques such as nanoparticle filling, fiber reinforcement, or polymer blending, the coating's abrasion resistance, thermal conductivity, or barrier properties can be specifically enhanced to meet the demands of special operating conditions.

Epoxy Resin: Coated internally and externally with epoxy resin, offering excellent corrosion resistance and adhesion. Commonly used in water supply, drainage, fire protection, and chemical pipelines.

Polyethylene (PE): Coated internally or externally, providing corrosion resistance, abrasion resistance, and insulation. Primarily used for buried pipelines.

Polypropylene (PPR): Mainly used as an inner lining, featuring high-temperature resistance, pressure resistance, and non-toxicity. Widely applied in drinking water systems.

Polyvinyl Chloride (PVC): Lining material with corrosion resistance but limited temperature tolerance.

Modified Bitumen (Coal Tar Pitch): External anti-corrosion coating that is smooth and dense, resistant to salt alkali and soil microbial corrosion.

The following are common organic-coated steel pipes used in engineering projects.

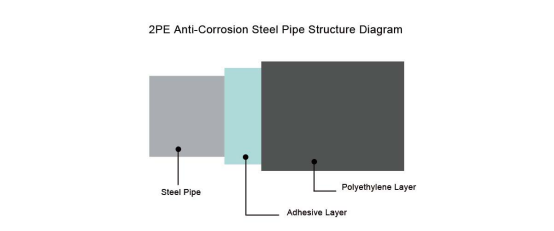

2PE Anti-Corrosion Steel Pipe

Also known as two-layer polyethylene anti-corrosion steel pipe, its structure consists of an adhesive layer (AD) as the first layer and polyethylene (PE) as the second layer. The two materials fuse into a single anti-corrosion layer, with each layer's thickness identical to that of three-layer PE anti-corrosion steel pipes.

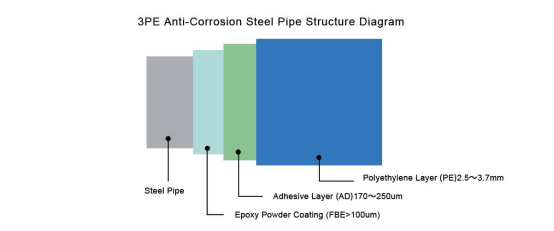

3PE Anti-Corrosion Steel Pipe

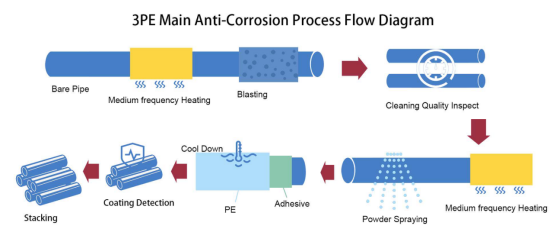

is meticulously constructed with a three-layer structure: the base layer consists of epoxy powder (FBE) with a thickness exceeding 100μm; followed by the second layer of adhesive (AD) with a thickness controlled between 170–250μm; and the outermost layer comprises polyethylene (PE) with a thickness of 2.5–3.7mm. During production, these three materials are skillfully blended and fused together. Through specialized processing, they form a robust bond with the steel pipe surface, creating an exceptional corrosion-resistant coating.

In the three-layer structure, the primary function of the fusion-bonded epoxy powder coating is to: form a continuous film that bonds directly to the steel pipe surface, providing excellent chemical corrosion resistance and cathodic delamination resistance; react with the active groups of the intermediate adhesive layer to form a chemical bond, ensuring the overall anti-corrosion layer maintains good adhesion at elevated temperatures. The intermediate layer typically consists of a copolymer adhesive, primarily composed of polyolefins, with vinyl copolymer adhesives being the most widely adopted option. The polar functional groups of the copolymer adhesive react with the epoxy groups in the fusion-bonded epoxy powder coating to form hydrogen bonds or chemical bonds, enabling strong adhesion between the intermediate layer and the base layer. Meanwhile, the non-polar ethylene segments exhibit excellent affinity with the polyethylene topcoat, ensuring strong adhesion between the intermediate layer and the topcoat as well. The primary function of the polyethylene surface layer is to provide mechanical protection and corrosion resistance, serving the same purpose as the traditional two-layer polyethylene anti-corrosion coating.

In terms of corrosion resistance, 3PE corrosion-resistant steel pipes offer superior protection due to their additional epoxy resin layer. Epoxy powder exhibits excellent corrosion resistance, mechanical properties, and strong resistance to cathodic delamination. It effectively blocks moisture and oxygen penetration, thereby reducing the risk of steel pipe corrosion. The 3PE anti-corrosion technology integrates the superior properties of both epoxy coating and extruded polyethylene layers. It combines the interface characteristics and chemical resistance of the epoxy coating with the mechanical protective advantages of the extruded polyethylene layer, significantly enhancing the performance of each component. Additionally, the three-layer structure enhances overall protective capability, making it particularly suitable for underground or humid environments. While 2PE corrosion-resistant steel pipes also possess certain anti-corrosion properties, their protective effectiveness is relatively weaker due to the absence of the third epoxy resin layer. They are more suitable for environments less prone to severe corrosion.

TPEP anti-corrosion coating represents an upgraded optimization of the 3PE system. The full name of TPEP anti-corrosion steel pipe is “Internal Fusion-Bonded Epoxy with External 3PE Anti-Corrosion Steel Pipe.” It uses steel pipe as the base material, with the inner wall treated using a thermally fused epoxy powder anti-corrosion method. The powder is heated to high temperatures, fused, and uniformly coated onto the steel pipe surface to form a steel-plastic composite layer. The outer wall employs a three-layer structure of polyethylene anti-corrosion coating.

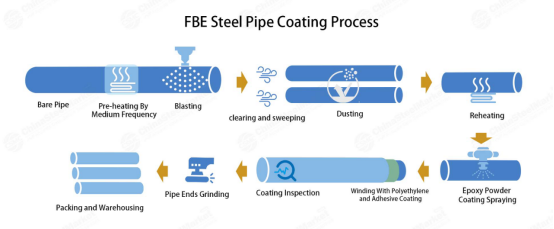

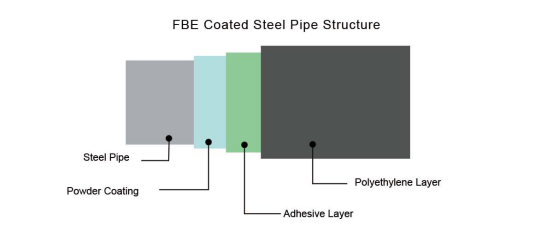

FBE Coating

FBE-coated steel pipes are steel pipes coated with epoxy resin (FBE). The epoxy resin is applied to the pipe surface and then heated to cure, forming a robust protective layer that enhances the pipeline's corrosion resistance. This coating effectively prevents corrosion caused by external environmental factors such as water, soil, and salt, significantly extending the pipeline's service life.

FBE-coated steel pipes not only offer outstanding corrosion resistance but also feature uniform coating thickness, strong adhesion, and high-temperature resistance. They are commonly used in underground or submerged pipeline projects, particularly in harsh environmental conditions such as high humidity and corrosive soils.

As demand for pipeline solutions grows across global industries, the market for FBE (Fusion-Bonded Epoxy) coated steel pipes is expanding rapidly. Particularly in sectors like energy, chemicals, water treatment, and municipal infrastructure, the increasing need for highly corrosion-resistant and durable pipelines is driving widespread adoption of FBE-coated steel pipes. Combining enhanced coating technology with environmental benefits and sustainability imperatives, FBE-coated steel pipes are emerging as a critical material for green infrastructure and sustainable development due to their superior corrosion resistance and extended service life. As environmental regulations become increasingly stringent, FBE-coated steel pipes will play an ever more vital role.

Polyurethane Insulated Steel Pipe Anti-Corrosion Coating

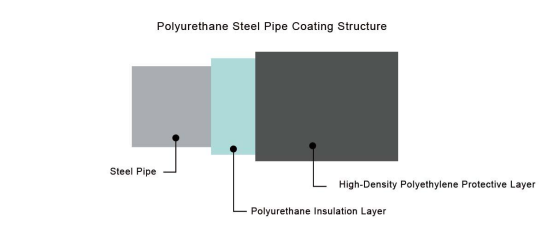

Polyurethane pipes, particularly direct-buried insulated pipes, feature a three-layer structure comprising a working steel pipe layer, a polyurethane insulation layer, and a high-density polyethylene protective layer. They offer outstanding anti-corrosion, insulation, and mechanical properties with a service life exceeding 50 years. Widely adopted in urban district heating systems, these pipes effectively reduce project costs and heat loss while accelerating construction progress.

Epoxy-Coated Steel Pipe with Internal and External Coatings

Epoxy-coated steel pipe with internal and external coatings is a new type of steel-plastic composite pipe. It consists of a steel pipe substrate, an internal epoxy resin coating, and an external polyethylene coating, offering excellent mechanical properties along with corrosion resistance and aging resistance.

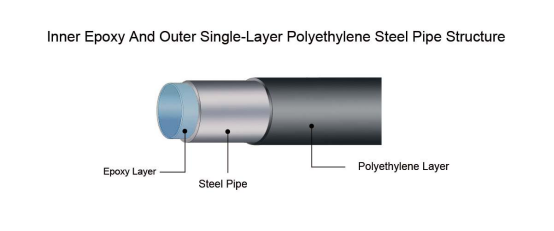

Inner Epoxy and Outer Single-Layer Polyethylene Steel Pipe Structure:

1. Steel Pipe Base Material: Seamless steel pipe, electric welded steel pipe (straight weld seam, spiral weld seam)

2. Internal Anti-Corrosion Coating: Sanitary-grade fusion-bonded epoxy powder coating, heavy-duty anti-corrosion fusion-bonded epoxy resin powder.

3. External Anti-Corrosion Coating: Thermoplastic single-layer polyethylene powder coating.

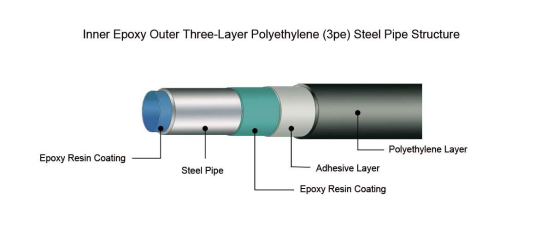

Inner Epoxy Outer Three-Layer Polyethylene (3PE) Steel Pipe Structure

1. Steel Pipe Base Material: Seamless steel pipe, electric welded steel pipe (straight weld seam, spiral weld seam)

2. Internal Anti-corrosion Coating: Sanitary-grade fusion-bonded epoxy powder coating, heavy-duty fusion-bonded epoxy resin powder.

3. External Anti-corrosion Coating: Thermoplastic three-layer polyethylene coating. The base layer consists of fusion-bonded epoxy resin powder, the intermediate layer is thermoplastic adhesive, and the outer layer is high-density polyethylene.

With growing societal focus on environmental protection and sustainable development, epoxy resin steel pipes—as an eco-friendly composite material—offer outstanding corrosion resistance and extended service life thanks to their epoxy resin coating. This significantly reduces environmental pollution and resource waste caused by corrosion. By lowering maintenance frequency and replacement needs, they enhance resource utilization efficiency. Their durability and green credentials also enable widespread application in water supply, drainage, and heating systems, supporting green building and sustainable urban development. Furthermore, this material contributes to reduced energy consumption and carbon emissions during both production and application, aligning with modern industry's demands for environmental protection and sustainable development. It provides an effective solution for advancing resource conservation and environmental stewardship.

Inorganic Coatings

Inorganic non-metallic coating systems occupy specific market segments due to their unique chemical inertness, high thermal stability, and environmental friendliness. Cementitious linings stand out as a cost-effective solution, widely used in large-diameter water and sewage pipelines. They not only provide a physical barrier but also create an alkaline environment through hydration products, passivating steel surfaces to further inhibit corrosion. Ceramic coatings, such as alumina, silicon carbide, or ceramic-metal composites, remain irreplaceable under extreme operating conditions. Their exceptional hardness, wear resistance, and ability to withstand temperatures exceeding 1000°C make them essential for applications like coal mill pipelines in thermal power plants, catalytic cracking units in petrochemical industries, and high-abrasion slurry pipelines in mining operations.

Cement mortar lining: An internal coating used for conveying water, gas, and other substances, providing corrosion resistance and enhancing smoothness.

Ceramic coating: A high-performance coating offering wear resistance, high-temperature resistance, and corrosion resistance for demanding environments.

Metal Coatings

The protective mechanism of metal coating systems is unique, primarily relying on electrochemical protection. Hot-dip galvanizing is the longest-established process, where molten zinc metallurgically bonds with the steel substrate to form a zinc-iron alloy layer and a pure zinc layer, providing long-term sacrificial anode protection. Its upgraded variant, zinc-aluminum-magnesium coating, significantly enhances edge protection and corrosion resistance by adding aluminum and magnesium to the bath solution. This makes it particularly suitable for applications requiring shear processing, such as building photovoltaic brackets and cable trays. Thermal sprayed metal coatings, such as arc-sprayed zinc, aluminum, or zinc-aluminum alloys, offer advantages in on-site construction, repairing large steel structures, and providing high-temperature oxidation resistance. Additionally, intermetallic compound coatings formed through diffusion processes, like aluminizing or zinc diffusion, deliver exceptional resistance to high-temperature oxidation and corrosion in specific media.

3. Inspection and Transportation of Coated Steel Pipes

3.1 Relevant Inspection Items

3.1.1 Coating Appearance Inspection

· Inspection Items: Whether the coating surface is uniform, and whether there are any bubbles, cracks, peeling, contaminants, or impurities.

· Inspection Method: Visual inspection or detailed examination using a magnifying glass.

3.1.2 Coating Thickness Inspection

· Inspection Content: Verify whether the coating thickness meets design specifications. Coatings that are too thick or too thin may compromise the protective effectiveness and service life of steel pipes.

· Inspection Methods: Typically performed using coating thickness gauges or other specialized equipment, commonly employing magnetic particle thickness measurement or eddy current thickness measurement.

3.1.3 Coating Adhesion Testing

· Inspection Content: Evaluate the bonding strength between the coating and the steel pipe substrate, as well as the adhesion between the coating and the pipe surface, to ensure the coating does not peel off.

· Testing Methods: The cross-hatch adhesion test or pull-off test (e.g., using a tensile tester) may be employed for evaluation.

3.1.4 Coating Hardness Testing

· Inspection Content: Verify coating hardness meets standards to ensure wear and scratch resistance during use.

· Testing Methods: Common hardness testing methods include the pencil hardness test and the Mohs hardness test.

3.1.5 Coating Corrosion Resistance Performance Testing

· Inspection Content: Verify whether the coating's corrosion protection performance for steel pipes meets requirements.

· Testing Methods: Commonly used methods include salt spray testing, humidity testing, immersion testing, etc.

3.1.6 Coating Temperature Resistance Testing

· Inspection Content: Verify whether the coating can withstand specified high or low temperature conditions to prevent performance degradation due to temperature fluctuations.

· Testing Method: Expose coated steel pipes to high or low temperature environments for a specified duration, then observe for changes such as discoloration, cracking, or peeling.

3.1.7 Chemical Corrosion Resistance Test of Coatings

· Test Scope: Evaluate the coating's ability to resist corrosion from various chemicals (e.g., acids, alkalis, solvents).

· Test Method: Immerse coated steel pipes in corresponding chemicals and observe the coating's reaction and extent of damage.

3.1.8 Coating Bend Test

· Inspection Content: Test whether the coating cracks or peels off when the steel pipe is bent.

· Inspection Method: Bend the coated steel pipe to a specified angle and inspect whether the coating cracks or peels off.

3.1.9 Gas and Water Tightness Testing of Coatings

· Inspection Content: For steel pipes with special-purpose coatings, the coating must exhibit excellent gas and water tightness to prevent substance leakage.

· Testing Method: Conduct pneumatic or hydraulic pressure tests to verify the pipe's sealing integrity.

3.1.10 Coating UV Resistance Testing

· Test Scope: Evaluate coating durability under ultraviolet radiation to prevent fading, aging, and other degradation caused by prolonged sun exposure.

· Testing Method: Utilize an ultraviolet aging test chamber to simulate sunlight UV exposure, assessing the coating's weather resistance and UV aging resistance.

3.1.11 Coating Peel Strength Test

· Inspection Content: Tests whether the coating easily peels off the steel pipe surface, particularly under pressure, friction, or external force.

· Testing Method: Conducted using a peel test, typically performed on standardized equipment.

3.2 Transportation of Coated Steel Pipes

The transportation of coated steel pipes is a crucial link between production and application. Its core is to ensure that the coating, the core protective layer, is not damaged before arriving at the site. Physical collisions, environmental erosion, and improper handling during transportation can directly damage the integrity of the coating, thereby affecting the corrosion resistance and design life of the steel pipe, causing the strict production and quality control in the early stages to be in vain. Therefore, systematic protection must be implemented throughout the entire process of packaging, loading, transportation, and warehousing.

3.2.1 General core principles and protective measures for transportation

The transportation management of coated steel pipes should be carried out around three core principles: preventing mechanical damage, isolating from environmental corrosion, and standardizing operating procedures. Mechanical damage mainly originates from the pressure and scratches during hoisting and binding, as well as collisions and friction during transportation. Therefore, high-strength protective caps must be installed at both ends of each steel pipe, which is a key line of defense against damage to the coating edges by the suspension rope. The pipe body should be wrapped according to the coating characteristics: for soft coatings such as three-layer polyethylene, a woven fabric composite film should be used to wrap the entire pipe body for protection, and direct contact with steel wire rope is strictly prohibited; for hard coatings such as fusion bonded epoxy, thick paper or felt should be used for wrapping and isolation. All bindings should be done using wide nylon straps or rubber-lined steel straps to avoid indentations.

3.2.2 Specific operating procedures for daily domestic shipments

In domestic road or rail transport, standardized operation is the basis for ensuring the integrity of the coating. During loading, steel pipes should be stacked stably on the vehicle, with aligned wooden blocks used to separate the layers to prevent damage to the coating and deformation of the pipe body due to uneven weight or bumps. Special nylon lifting slings must be used for loading and unloading, and the principle of "lifting and placing gently" must be strictly followed. Throwing, rolling, or using unprotected wire ropes for lifting is strictly prohibited. During transportation, goods must be effectively secured to prevent them from moving or colliding.

Warehousing management after arrival at the destination is an extension of the transportation process. Steel pipes should be stored in a flat, well-drained area and kept elevated and covered to avoid prolonged exposure to sun and rain. At the same time, clear and complete cargo identification and accompanying documents are essential. They should clearly indicate product specifications, coating type, and operational warnings such as "handle with care" and "keep away from moisture" to ensure that information is transmitted accurately during handover and subsequent handling.

3.2.3 Special requirements and risk management of international import and export transportation

International transportation, especially ocean shipping, is complex, has a long cycle, and has many uncontrollable environmental factors, which puts forward higher requirements for protection. The packaging must be reinforced and upgraded to adapt to the maritime environment. All wooden materials used for support and padding must comply with ISPM 15 international standards, be fumigated or heat-treated, and bear official markings; otherwise, they may face the risk of being returned or subject to forced disposal at the port of destination.

Container loading is a critical step in risk control. Ensure the box is clean and dry before packing. When loading, the goods must be placed tightly from both sides inside the container, and cushioning material must be placed at all contact points with the container walls and bottom. After loading, the cargo must be thoroughly reinforced in multiple directions and at multiple points using nylon straps, timber supports, and inflatable bladders to ensure that the cargo cannot move at all during the turbulence of long-distance sea transport. This is the most effective measure to prevent the coating from being damaged by collisions caused by cargo shifting or jumping. In addition, it is recommended to place sufficient desiccant inside the container to absorb the moisture brought by "container rain".

In international trade, complete documentation and insurance are important means of risk transfer. The accompanying documents should specifically specify the protection requirements for the goods. The goods must be insured under "all risks" insurance that covers the entire transportation process, and the insurance must clearly cover coating damage caused by improper loading or unloading, or packaging problems. When unloading goods at the port of destination, an on-site inspection should be conducted as much as possible. If damaged packaging or signs of displacement are found, photos should be taken immediately as evidence and noted on the receipt documents for future claims to protect one's rights.

In conclusion, the transportation of coated steel pipes is not a simple logistics activity, but a precise protective engineering project that runs throughout the entire process. It requires every participant, from factory packaging to final unloading, to have a deep understanding of the coating's value and fragility, and to work together to safeguard this value through rigorous and professional operations, ensuring that the engineering materials are put into construction in the best possible condition.

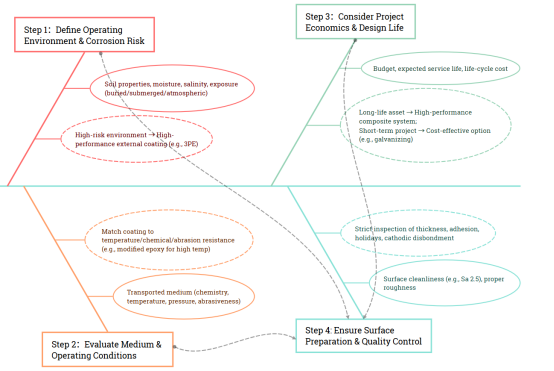

4. How to Select the Appropriate Coating for an Engineering Project

In engineering projects, selecting the appropriate steel pipe coating is a crucial step in ensuring the long-term safe and stable operation of pipelines. A suitable coating can not only effectively improve the corrosion resistance of steel pipes, but also extend their service life and reduce maintenance costs. Therefore, when selecting a coating, multiple factors such as the environmental conditions of the project, the characteristics of the medium, the expected life and the budget must be considered.

First, the coating type should be determined based on the operating environment and corrosion risk of the pipeline.

In buried or damp environments, geological soil, moisture, and salinity can exacerbate corrosion. Such environments typically require high-performance external anti-corrosion coatings, such as three-layer polyethylene (3PE) coatings, which consist of an epoxy primer, an adhesive layer, and a polyethylene top layer. These coatings provide excellent mechanical protection and waterproof barrier properties, making them suitable for high-corrosion-risk applications. In contrast, single-layer fusion-bonded epoxy (FBE) coatings are often used in conventional medium-temperature pipelines or as lining coatings due to their strong adhesion and good chemical corrosion resistance, and are very effective in resisting internal corrosion of the medium.

Secondly, the properties of the medium and operating conditions should be assessed.

For example, in pipelines transporting high-temperature, high-pressure, or corrosive chemical media, the temperature resistance, chemical resistance, and stability of coating materials are primary considerations. Some polymer coatings, such as thermosetting epoxy and polyethylene composite systems, can maintain good performance within a certain temperature range, while ordinary primers or traditional paint-type coatings may not be suitable for complex media environments.

Furthermore, project budget and expected service life are also important factors to consider when making a selection.

High-performance multilayer composite coating systems have a higher initial investment, but they are often more economical in the long run due to their low maintenance frequency and high durability. For temporary projects with short cycles or limited budgets, more cost-effective coatings, such as hot-dip galvanizing or single-layer epoxy coating, can be selected while meeting basic anti-corrosion requirements.

Finally, regardless of the type of coating chosen, attention should be paid to surface pretreatment and construction quality control.

No matter how high the performance of the coating system, if the substrate surface is not thoroughly cleaned and sandblasted to remove rust, the adhesion and protective effect of the coating to the steel pipe will be greatly reduced. Therefore, during the construction and acceptance phases, the relevant quality inspections mentioned above, such as coating thickness, adhesion, and uniformity, should be strictly carried out in accordance with the specifications.

In summary, selecting a suitable steel pipe coating involves multiple dimensions, including environmental assessment, working condition matching, economic considerations, and construction quality control. Only through comprehensive technical analysis and the development of reasonable solutions can the long-term corrosion resistance and stable operation of the engineering pipeline system be ensured.

5. Development Trends of Coating Technology

With the increasing demands on pipeline corrosion protection technology, coating technology is also facing new challenges and development opportunities. On the one hand, with increasingly stringent environmental policies, the environmental friendliness of coating production processes and materials will become an important direction for research and development; on the other hand, the high-temperature resistance, low-temperature resistance, and chemical corrosion resistance of coatings still need further optimization to cope with more demanding working environments.

In recent years, some new coating materials have been gradually applied to the steel pipe field. The surface coating technology of steel pipes will develop towards high performance, environmental protection and intelligence. The future of steel pipe coating technology is full of potential and innovation. As technology matures, industry standards and regulations will be gradually improved. From environmentally friendly materials and multifunctional integration to intelligent manufacturing, multiple trends will jointly drive the industry towards high efficiency, greenness, and economy. As a key industrial material, its advancements are not only about the technology itself, but also have a profound impact on many fields such as energy, transportation, and construction. CSMC will continue to focus on the future development of coating technology and actively provide useful information to its customers.

We sincerely hope that the information we provide can make more beneficial value. In addition, we sincerely invite you to leave valuable comments and advice on our website. We will follow your comments and advice at any time on our website.

CSMC-Empowering small and medium-scale steel purchasing.

Editor: Kyra Hana

Mail: cs@chinasteelmarket.com

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: