Rare earth elements, known as “industrial vitamins,” are added to steel to make it harder, tougher and stronger. Bao Gang United Steel's thin plate plant continues to optimize the production process of rare earth wear-resistant steel, promoting steady improvement in product performance. Since the beginning of this year, its wide and thick plate production line has supplied more than 4,000 tons of thin-gauge rare earth wear-resistant steel and more than 3,000 tons of thick-gauge products. What is particularly crucial is that Bao Gang United Steel has now achieved mass production and full coverage of rare earth wear-resistant steel of all specifications from 8mm to 60mm.

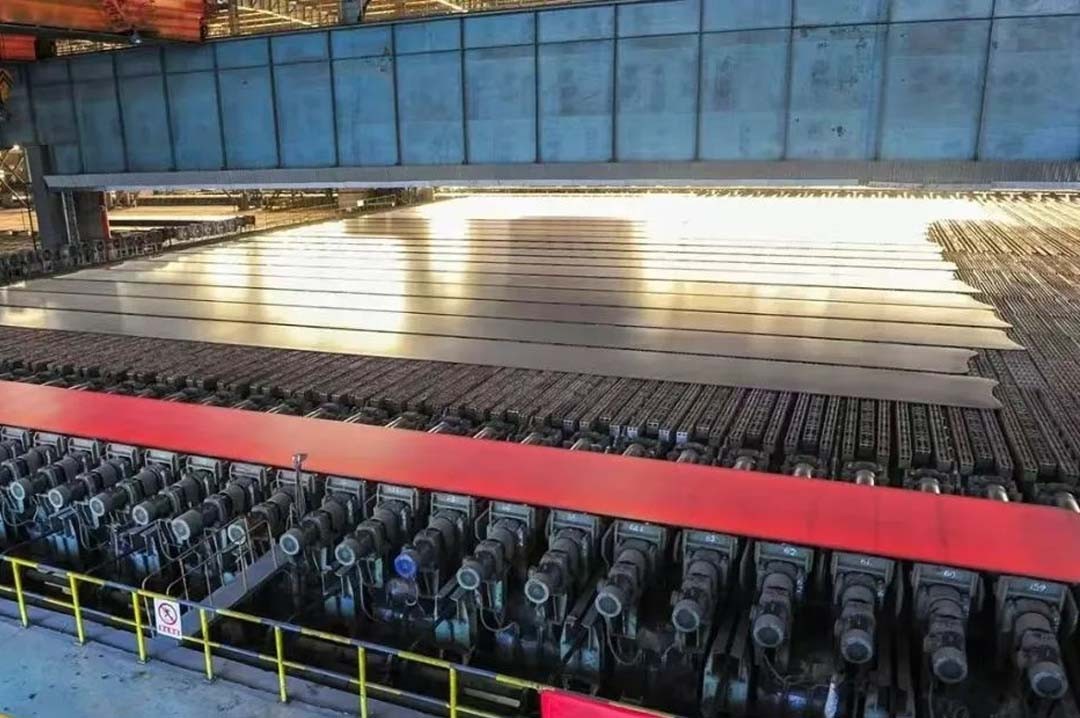

On August 19, the reporter met Wu Pengfei, technical director of the heat treatment area of Bao Gang United Steel's wide and thick plate production line. He said that rare earth elements play a significant role in steel materials. In the past, this production line mainly mass-produced intermediate-specification rare earth wear-resistant steel with a thickness of 20 to 30 mm. Faced with the market's growing demand for thin and thick specifications of products, Bao Gang United Steel has targeted high-end application areas. By carefully adjusting the form, method and amount of rare earth elements added, it has effectively optimized product performance and successfully expanded the thickness specifications of rare earth wear-resistant steel. In the heat-treated finished product warehouse, thin-gauge steel plates that are only 8 mm thick are neatly stacked. Wu Pengfei said that these products will be used for the processing of mining carriages. Their excellent plate shape makes welding easier, and their outstanding low-temperature impact toughness is especially suitable for the harsh environment of mining vehicles. The thick-gauge steel plates stored on the other side of the warehouse are several times thicker than the thin-gauge ones. It is reported that the difficulty of the thin-gauge process lies in controlling the plate shape, while the thick-gauge process needs to focus on overcoming the cracking problem caused by the "sandwich" phenomenon. To this end, thick-gauge products use a method of adding rare earth elements in combination with hardenability elements, aiming to improve the hardenability and low-temperature impact toughness of the core of the steel plate, thereby extending its service life. This type of process optimization successfully addressed the core quality challenges of thick-gauge products. "Although these products are very thin, their performance fully meets customers' customized needs," said Wu Pengfei.

Thanks to its improved performance, Bao Gang United Steel's rare earth wear-resistant steel has won the favor of major domestic coal machinery manufacturers, and orders have been steadily increasing. It is understood that its rare earth wear-resistant rails have been used in major heavy-load railway lines in China, significantly extending the life of the rails and reducing maintenance costs. At the same time, high-wear-resistant rare earth steel is used in scrapers, mining truck carriages and other equipment, with its compressive strength increased by more than 80%, and is highly recognized by domestic and foreign customers.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: